Share to

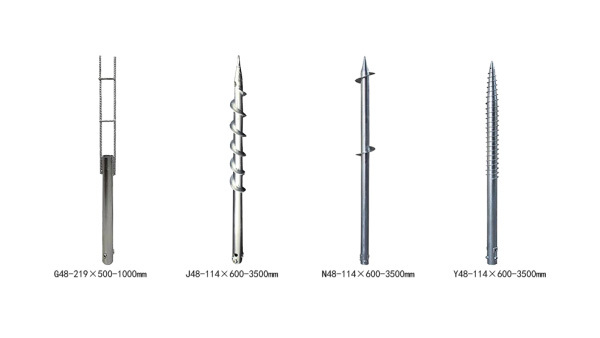

Photovoltaic ground pile

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Specification

Size(mm)

OD(mm)

Length(mm)

Material

Thickness

Finish

G48-219×500-1000

48 60 68 76 89 114 141 168 219

500-6000

Q235B Q355B Q420B

2.5-6mm

HDG≥60μm

J48-114×600-3500

48 60 68 76 89 114

600-3500

Q235B Q355B Q420B

2.5-4mm

HDG≥80μm

N48-114×600-3500

48 60 68 76 89 114

600-3500

Q235B Q355B Q420B

2.5-4mm

HDG≥80μm

Y48-114×600-3500

48 60 68 76 89 114

600-3500

Q235B Q355B Q420B

2.5-4mm

HDG≥80μm

Operating:

Storage: Products should be stored in a dry and ventilated warehouse to prevent rust and pollution. Products should be classified and stacked, with labels indicating the type, specification and batch number, and placed securely to prevent deformation and damage.

Loading: When lifting, components should be prevented from damage or deformation. When loading, they should be placed stably, in a moderate position, and reliably reinforced. Danger warning signs should be hung when transporting overlong, overwide, and overhigh components. Pay attention to protecting the safety of roads, bridges, communications, power and other facilities.

Transport: Steel structure components must be properly tied during transportation and hoisting to prevent deformation, damage and breakage of the galvanized layer.

The Photovoltaic Ground Pile is an essential support structure used in the installation of solar energy systems on the ground. This component is designed to anchor solar panel arrays securely to the ground, providing stability and ensuring that the panels remain properly aligned to capture sunlight effectively. Constructed from durable materials such as galvanized steel or aluminum, the photovoltaic ground pile is built to withstand various environmental conditions and provide long-term reliability.

The primary function of the ground pile is to offer a solid foundation for solar panel installations in open fields or other ground-mounted applications. Its design typically includes a stake or post that is driven into the ground, along with a mounting bracket or platform where the solar panels are attached. This configuration allows for easy installation and adjustment of the panels to achieve the optimal angle for sunlight exposure.

One of the significant advantages of the photovoltaic ground pile is its ability to be installed in a variety of soil types and ground conditions. The pile's design may include features such as adjustable lengths or additional support components to accommodate different ground conditions and ensure a stable installation. This flexibility makes the ground pile suitable for use in diverse environments, from flat agricultural fields to uneven terrain.

The durability of the photovoltaic ground pile is crucial for maintaining the stability of the solar panel array over time. The pile is engineered to resist corrosion and other forms of wear and tear, ensuring that it remains effective and reliable throughout its service life. This durability is essential for minimizing maintenance requirements and extending the lifespan of the solar energy system.

Additionally, the photovoltaic ground pile is designed with ease of installation in mind. The pile's components are often pre-fabricated and include features that simplify the installation process, such as pre-drilled holes or integrated mounting brackets. This user-friendly design helps to reduce installation time and costs, making it a practical choice for large-scale solar projects.

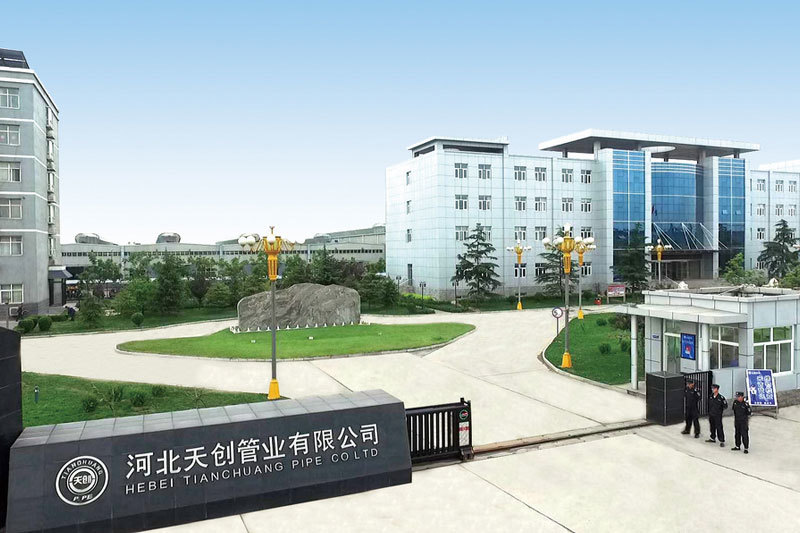

Company introduction

Tianchuang takes great pride in being one of the foremost highway guardrail suppliers and manufacturers in China, delivering premium-quality products to our valued customers. We have various types of highway guardrails for sale, including W Beam Crash Barriers, Thrie Beam Highway Guardrails. Additionally, we offer various protection methods to suit your specific needs, including Galvanizing and Spray Coating. There's always a steel highway guardrail perfectly tailored to meet your requirements.

Tianchuang Highway Guardrail Production Facilities & Capabilities

|

|

|

|

|

|

|

|

Certificate

Compliance with Industry Standards: The crash barrier panels produced by Tianchuang fully adhere to the requirements of the YB4081-92 standard. This commitment to compliance ensures that the guardrails meet rigorous safety standards and performance expectations.

High-strength Materials: The highway guardrails manufactured by Tianchuang are made from stainless steel, offering exceptional strength and durability. This choice of material guarantees longevity and reliability, even in challenging environmental conditions.

Expertise in Highway Lane Division Protection: The utility model guardrail boards provided by Tianchuang are primarily designed for the division protection of highway lanes. This expertise ensures that their crash barriers are optimized for ensuring road safety and preventing accidents.

Why Choose Tianchuang

Professional R&D Team: As a professional highway guardrail supplier, Tianchuang has over 1,800 employees, including 12 senior engineers and 150 technicians working in a number of workshops.

Cutting-edge Technology: Tianchuang embraces cutting-edge domestic production technology, including the adoption of advanced equipment like the US R425 rolling mill. The use of precision feeding and punching, 18-roller slow forming, and computer cut-off techniques ensures the utmost precision in crafting crash barrier panels.

Large-scale Production Capacity: Our company is equipped with 4 corrugated beam guardrail sheet press modeling lines, 11 hot dip galvanization lines, and 1 powder coating and PVC coating line. With such advanced facilities, we proudly maintain a strong capacity for large-scale production, efficiently catering to projects of varying sizes. This capability ensures timely delivery and completion of assignments within strict timelines, facilitating successful project execution.

Tianchuang's Cooperative Project

Beijing Daxing Airport Highway-Xinguomen First Road

Beijing Yan Chong Highway-To Build Quality Engineering Escort 2022 Beijing Winter Olympics

Photovoltaic ground pile

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products

Content update in progress

Quote Now

Our staff will contact you within 24 hours (working days). If you need other services,

please call the service hotline:+86-310-6668080